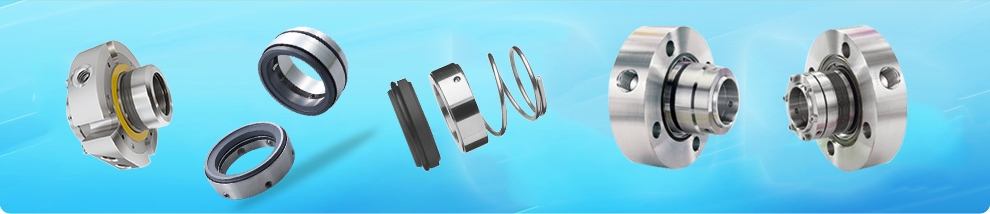

DRY RUNNING MIXER SEALS

Material

Seal Face :Carbon, Ceramic, TC

Secondary Seals :Viton/PTFE/Nitrile

Metal Parts :SS 316, 904L

Dry Running Agitator Seals

Dry Running Mixer Seals is a multiple spring externally mounted,Reverse Balanced Seal with O-ring as secondary sealing member.

Dry Running Agitator Seals are available with cartridge, non-cartridge & with bearing assembly. Dry Running Seals design eliminates the need of auxiliary equipment for cooling & lubrication that is required for mixer application.Since there is no use of barrier fluid, thus eliminates the possibility of product contamination.

Dry Running Seals don’t require any external media for lubricating the faces, that is why they are known as dry running seals.

Application

Dry running Mixer seals are widely used in top entry low RPM mixers, agitators & vessels in pharmaceuticals & chemical industries.

Operating Limits

Pressure : up to 1.40 MPa

Temperature :(-)50°C to (+)150°C

Speed : up to 1 m/s

Sizes : 25 mm to 100 mm